Service Factor

Service factor (f.s.) is a way of considering service life. A gearhead used in ideal conditions with uniform (normal duty), 8 hours per day running time and a maximum of 5 starts per hour has a service factor of 1, this gearhead can be expected to give in the region of 15,000 service hours use.

However if the gearhead is subjected to more arduous conditions and duty cycles then this can erode the service hours use, but it can be compensated in your selection by choosing the expected load of the gearbox in the filter selection area of the home page which will result in the correct size of gearhead being selected.

All selections in this site are based on 8 hours per day usage and a maximum of 5 starts per hour if your application exceeds these figures please speak to a Transdrive applications engineer who will gladly advise on the correct selection.

The service factor (f.s.) depends on the operating conditions the gearhead is subjected to.

The parameters that need to be taken into consideration to select the most adequate service factor Correctly are:-

Considerations:-

- Type of load of the operated machine: A - B – C see below

- Length of daily operating time: hours/day. All selections on this site are based on 8 hours usage per day.

- Start-up frequency: starts/hour. All selections on this site are based on a maximum of 5 starts per hour.

LOAD

- A - Uniform (Normal Duty)

- B - Moderate shock Load

- C - Heavy Shock Load

A - Uniform (Normal Duty)

Screw feeders for light materials, fans, assembly lines, conveyor belts for light materials, small mixers, lifts, cleaning machines, fillers, control machines.

B – Moderate Shock Load

Winding devices, woodworking machine feeders, goods lifts, balancers, threading machines, medium mixers, conveyor belts for heavy materials, winches, sliding doors, fertilizer scrapers, packing machines, concrete mixers, crane mechanisms, milling cutters, folding machines, gear pumps.

C - Heavy Shock Load

Mixers for heavy materials, shears, presses, centrifuges, rotating supports, winches and lifts for heavy materials, grinding lathes, stone mills, bucket elevators, drilling machines, hammer mills, cam presses, folding machines, turntables, tumbling barrels, vibrators, shredders.

For very heavy applications such as quarries and steel works please speak to a Transdrive application engineer who will gladly advise on the correct selection.

View Catalogue Page

View Catalogue Page

View Catalogue Page

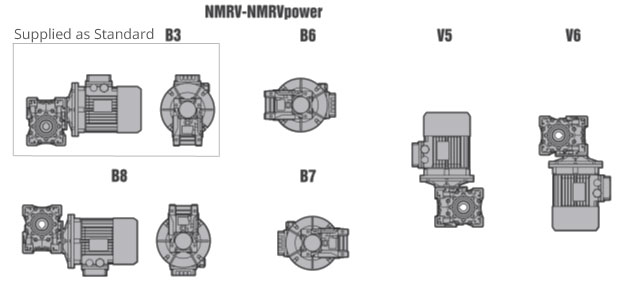

Geared Motor Direct: Motovario Right Angled Geared Motors

Geared Motor Direct: Motovario Right Angled Geared Motors